Technical information and details

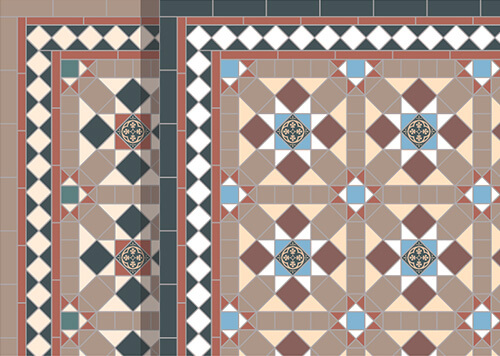

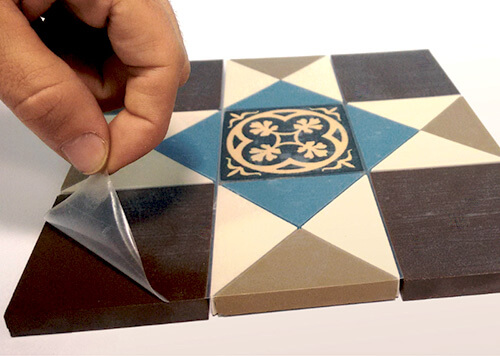

The main range of geometric tiles we supply are manufactured by Winckelmans, who have been producing high quality ceramic floor tiles since the 1890's.

Unlike other pre-moulded tiles these have square edges and can be closely butted to recreate an accurate and authentic look. Original period tiled floors were based on the Imperial measurement system. All of the geometric components featured in this range of tiles are based on metric measurements.

Apart from a very subtle difference in size and colour, this range, as far as we are aware, is the closest to the original system of dust pressed pre-moulded tiles. The tiles are unglazed fully vitrified (heat treated) ceramic, coloured throughout and very robust.

For more information about the colours, shapes and dimensions of the ceramic tiles in our range please see the Colours and shapes page.

Range and classification standards

Floors of premises are classified in terms of the increasing levels of resistance and durability to the loads they carry and the ability to withstand wear and tear due to: Surface abrasion, damage from static or moving loads, water used for cleaning or from products and chemicals which are corrosive or stain.

Tiles are tested in order to determine their resistance to these factors and are classified in line with NF standards (French Norms). All our tiles conform to the NFP 61-405 standards (class B1 of the European EN176 standards). They comply with classifications U4, P4, E3 and C2 with the exception of the 20mm x 20mm, 50mm x 50mm and the relief design tiles which comply with P3). Our tiles, with their increased thickness (9mm), comply with the P45 standards.

In tests, results for all our products exceed the required industry standards.

Full vitrification of our tiles ensures they have a long life. Our products are durable, resistant and easily maintained. They are resistant to scratches from foot traffic and machinery passing over them. Our tiles maintain their original colour for many years and when adapted for industrial use, they are capable of heavy wear. With a very low porosity they can be used in all conditions, inside and out, on floors or walls and are equally suitable for dry and humid conditions.

Slip resistance

Report

CSIRO - Building Construction and Engineering

CERLABS European Network of National Ceramic Laboratories

Manufacturer: Winckelmans

Tile Description: 50mm x 50mm grey unglazed dry pressed ceramic tile

Determination of slip resistance using pendulum friction tester

Test carried out in accordance with AS/NZS 3661.1:1993

Slip resistance of pedestrian surfaces, Part 1: Requirements.

Appendix A. (Wet Slip)

Test Date: 5 January 1998

Results

Location: Ceramic Tile Laboratory

Sample: Unfixed

Cleaning: Acetone

Temperature: 23 centigrade

Rubber Type: S4

Mean coefficient of friction: 0.62

The compliance requirement is not less than: 0.40

and no specimen in that sample shall be less than: 0.35

Surface roughness (Rtm) mean: 30.3 microns

According to the UK Slip Resistance Group, a Rtm roughness value of at least 10 microns is needed in wet conditions, and it has elsewhere been suggested that at least 14 microns is required for ceramic, terrazzo and stone flooring.

DIN 51130 RValue slipperiness classification

In HSE Ramp Tests, our range of tiles comply with R10 specifications.

Tiles of 50mm and smaller when installed, and Orange peel anti-slip tiles are rated R11.

Pendulum test value (PTV)

Natural finish rating:

PTV +36, Barefoot B

Rice grain anti-slip rating:

PTV +36, Barefoot C

Orange peel anti-slip rating:

PTV +36, Barefoot C

Anti-Slip ratings may vary depending on tile size.

Declaration of performance

Technical data downloads

- Unglazed 20x20cm (pdf) 273KB

- Unglazed 15x15cm (pdf) 273KB

- Unglazed 10x10cm (pdf) 269KB

- Unglazed 5x5cm (pdf) 269KB

- Unglazed 2x2cm (pdf) 269KB