What are sheeted tiles?

Our innovative sheets of individual tiles enable the laying of complex mosaic designs quicker and more accurately, saving you money on installation and delivering outstandingly beautiful results.

Our bespoke, hand-assembled, sheeted tiles

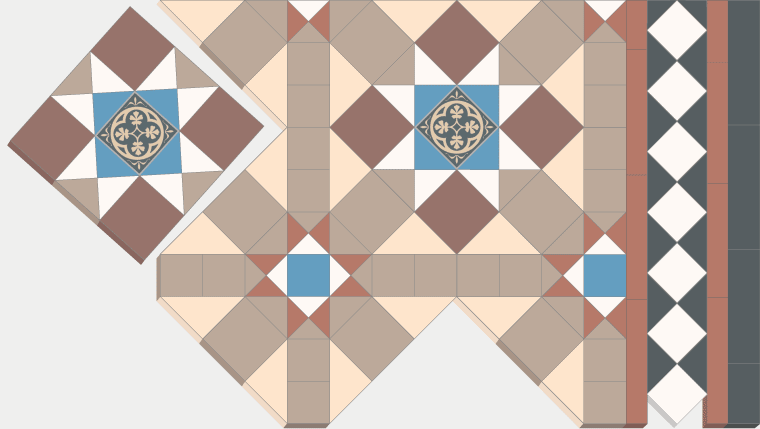

Nearly all of our geometric floor tile designs can be divided into sheets which are easy to handle and fit together perfectly.

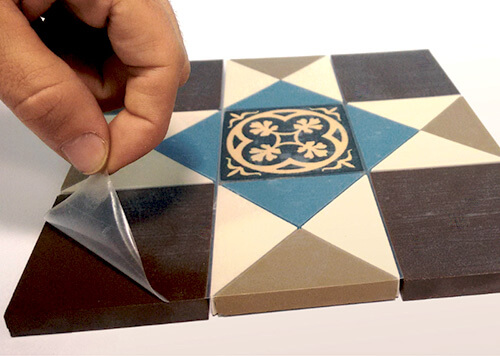

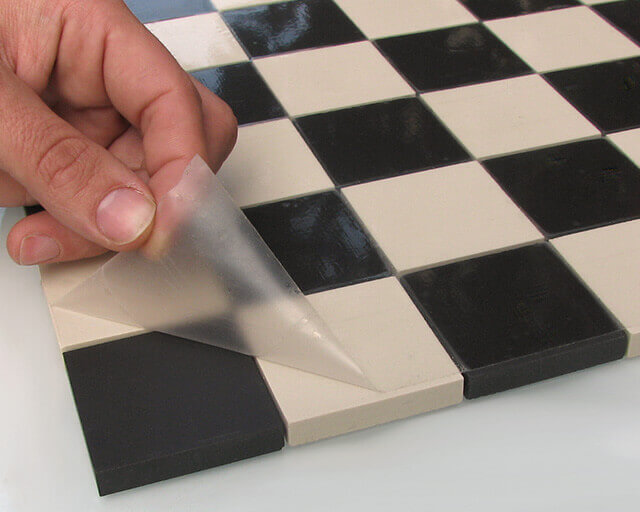

At our workshop, high-quality individual tiles are assembled to create repeating patterns, and a clear adhesive film is applied to the top.

The sheets of tiles are delivered with a detailed layout diagram and installation guidelines. The plastic film that holds the tiles in place is easily removed once the tiles are fixed and ready to grout.

Our tried and tested method has facilitated thousands of stunning installations over the past decade.

Benefits of sheeted tiles

Compared to factory-produced underside mesh

- Hand-assembled sheets have narrow grout lines

- Surface sheet protects the tiles from contamination

- There is 100% contact with the adhesive

- It's easy to cut and make adjustments to the design

- Provides leveling, minimising exposed edges

A made-to-measure solution

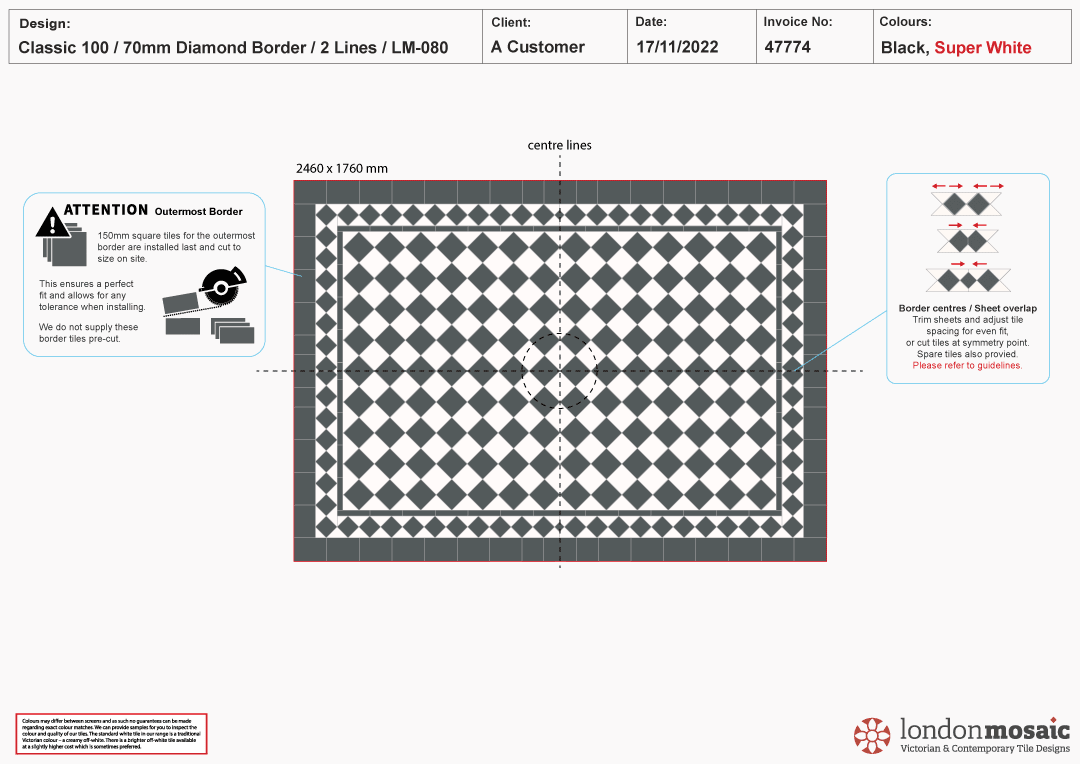

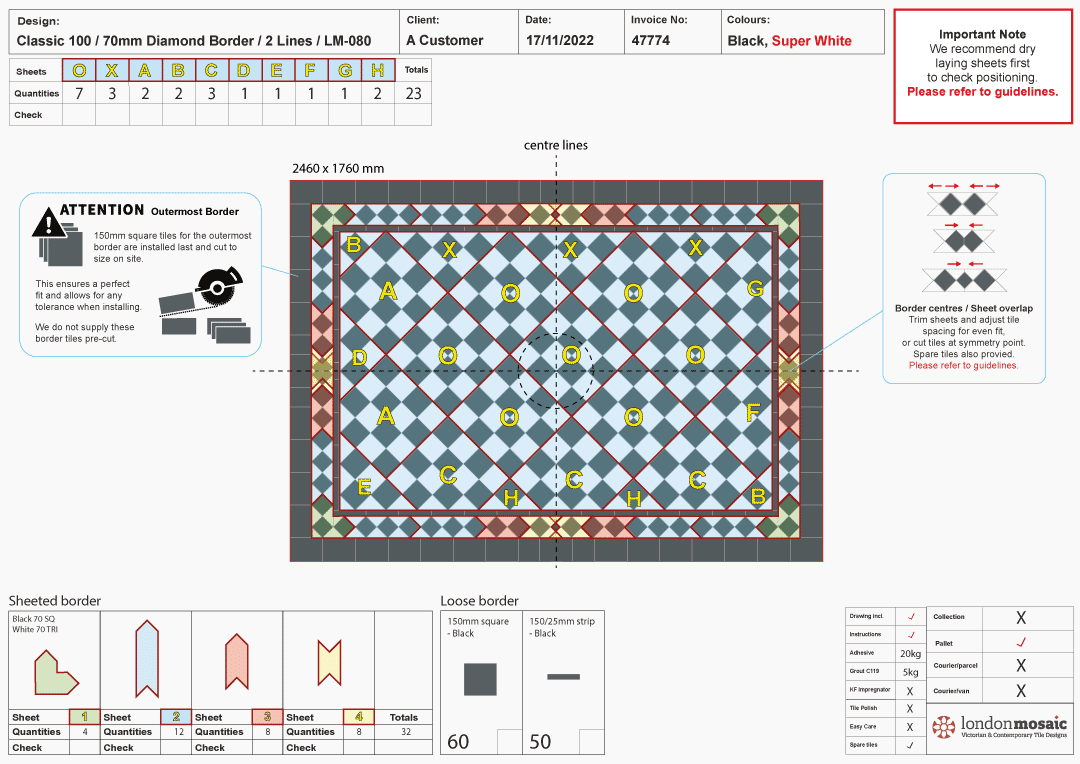

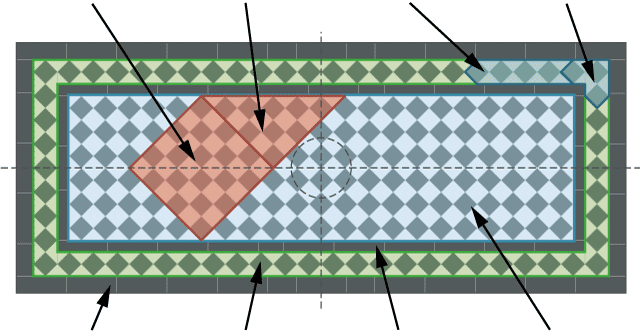

In order to create a bespoke layout using our sheeted system, we firstly create a scale plan based on the dimensions provided. This diagram is then sent to our clients for approval.

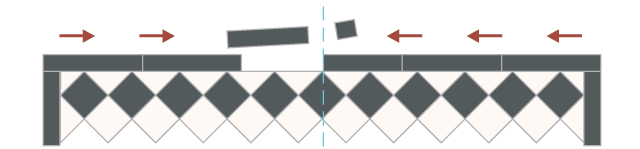

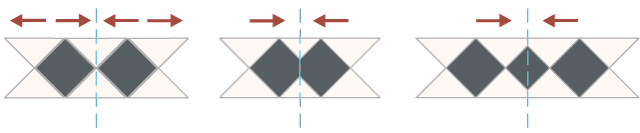

Most of the sheets used to populate the area are the same standard shape, but the edges of the field are formed with bespoke shapes. This ensures the field (or centre) features no loose tiles.

Each sheet is marked numerically or alphabetically, and a printed diagram is provided showing the exact layout and key information such as symmetrical mid-points and centre lines.

This system vastly reduces the amount of individual components in a geometric design for an accurate and trouble free installation.

The process

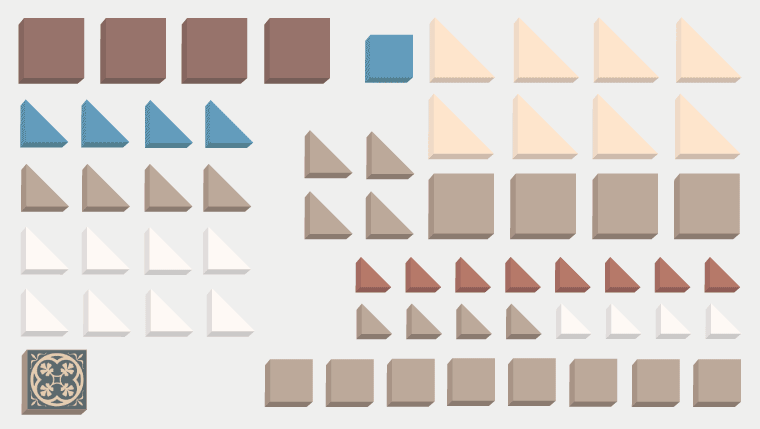

1 Individual high quality geometric tiles

2 Assembled by hand into bespoke sheets

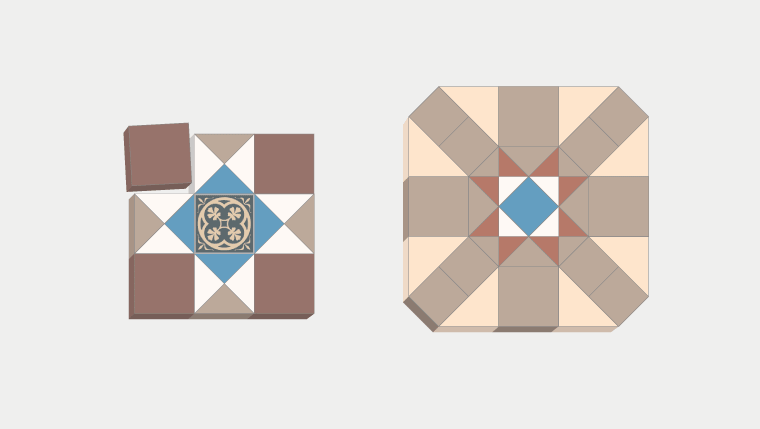

3 Sheets tessellate to create design

4 A beautiful and accurate installation

Glossary of design parts

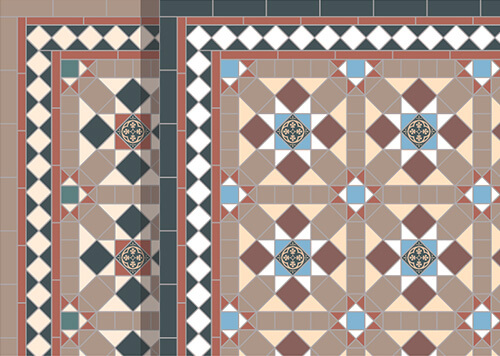

A Victorian tile design should be laid out symmetrically with the field pattern finishing on a whole or half tile prior to the border.

Border details

Both the inner and outermost border tiles are always supplied as a set of individual pieces to be fixed one by one.

The inner border line tiles are commonly supplied as 150 x 25 mm strips which are laid end to end surrounding the field. Requiring only a few cuts, these are also often referred to as pencil tiles and are always fixed once the field sheets have been set in place.

The decorative border element is always sheeted and is supplied in linear sections and corner sections. Because of the geometry of Victorian tiles, some adjustments may need to be made to tiles at the border centre - a method traditionally employed by period tilers. More details can be found in our Sheeted tile installation guidelines (link below).

The outermost border tile allows tolerance when fitting the design, accommodating for example, askew walls, pipe details or other architectural features. This tile is usually supplied as 150 x 150 mm square and is cut on site for a perfect fit.